Bread Robot

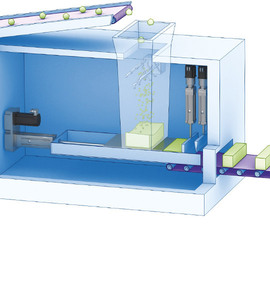

Two-axis packaging robots do considerable work in assembling and packing food items like baked goods, boxed cereal, boxed dairy products and mincemeat in trays. The system involves picking, placing, arranging and conveying individual items and the final packages. A wide range of Thomson components contribute to this vital food-processing function, including ball screws, guides, full linear motion systems and planetary gears and servo motors – all meeting strict washdown demands.

Two-axis packaging robots do considerable work in assembling and packing food items like baked goods, boxed cereal, boxed dairy products and mincemeat in trays. The system involves picking, placing, arranging and conveying individual items and the final packages. A wide range of Thomson components contribute to this vital food-processing function, including ball screws, guides, full linear motion systems and planetary gears and servo motors – all meeting strict washdown demands.

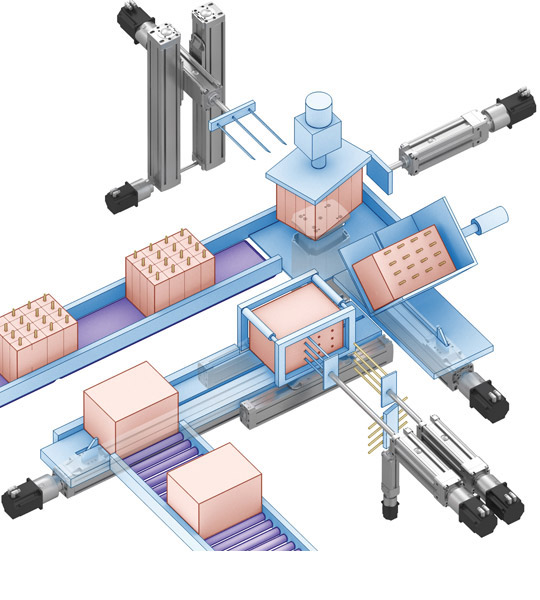

Belt Driven Linear Unit

Facilitates rapid transfer of in-process material to maximize line throughput.

Precision Linear Actuator

Accurately raises and lowers vertical gripper assembly to grasp and release product.

Planetary Gearhead and Servo Motor

Provides torque amplification and speed reduction to accurately position vertical axis on conveyor beds.

Linear Guide and Ball Screw Assembly

Accurately positions food and accounts for variation in product size.

English

English  Lietuvių

Lietuvių  Русский

Русский  Thomson’s components and solutions shine in high-throughput multi-axis applications such as assembly lines with skewers. Skewer units employ gearheads and clutches, brakes and resolvers and rodless actuators in optimal combinations. Skewer units can employ dual guides for raising and lowering, or these can be replaced with a single profile rail or two profile rails. These also employ clutches and gearboxes to complement the motor unit.

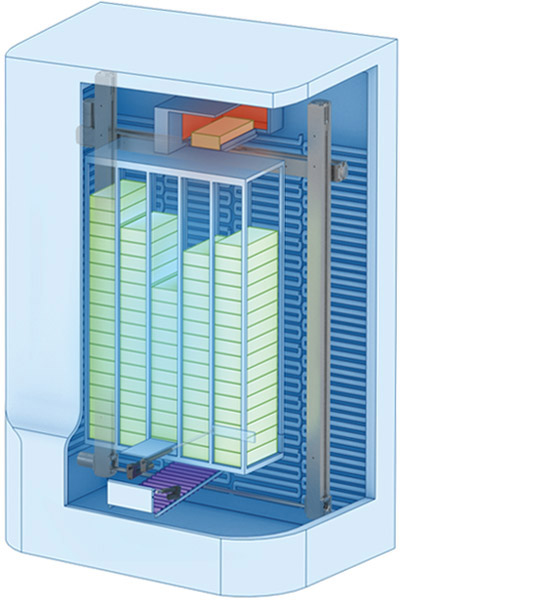

Thomson’s components and solutions shine in high-throughput multi-axis applications such as assembly lines with skewers. Skewer units employ gearheads and clutches, brakes and resolvers and rodless actuators in optimal combinations. Skewer units can employ dual guides for raising and lowering, or these can be replaced with a single profile rail or two profile rails. These also employ clutches and gearboxes to complement the motor unit. Actuators of multiple sizes, ball screws, gearheads and full linear motion systems combine to control the multiple stages in this application, where frozen dinner boxes are placed in a microwave and heated before being delivered to a hatch for the customer.

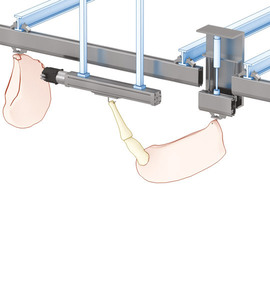

Actuators of multiple sizes, ball screws, gearheads and full linear motion systems combine to control the multiple stages in this application, where frozen dinner boxes are placed in a microwave and heated before being delivered to a hatch for the customer. These heavy-duty positioning machines promote safety by handling the hard work of positioning carcasses for deboning. In this application, round rail linear guides are employed in an elevator that brings product to an overhead monorail crane system. Horizontal motion is driven by a zero-setup linear motion assembly with a stainless steel Micron gearhead. These components must be extremely durable and must withstand high-pressure, caustic washdowns, to ensure food safety.

These heavy-duty positioning machines promote safety by handling the hard work of positioning carcasses for deboning. In this application, round rail linear guides are employed in an elevator that brings product to an overhead monorail crane system. Horizontal motion is driven by a zero-setup linear motion assembly with a stainless steel Micron gearhead. These components must be extremely durable and must withstand high-pressure, caustic washdowns, to ensure food safety.